The manufacturing industry is dealing with a multitude of changes. Many leaders are managing routine business challenges while being cautious of the ever-changing work landscape. Despite this, the manufacturing industry is building back fast. Undeterred by significant labor and supply chain challenges, it continues to maintain momentum. And in doing so, many manufacturing industry trends are coming to the surface.

But before we discuss these manufacturing industry trends, let’s look at the industry itself.

The manufacturing industry of today

The manufacturing industry is an essential element of the global economy. Its presence is most known in many diverse sectors such as healthcare, clothing and electronics. Without fulfilling the demand of these high-quality production and services, the world would come to a standstill.

Understanding the industry’s importance

When we think closer to home, it’s impact is enormous. Accounting for approximately $174 billion of Canada’s GDP, it represents more that 10% of Canada’s overall goods and services. And this very total equates to $364 billion in merchandise exports per year.

Aside from these numbers, labor shortages have continued to cause complexities. Organizations have struggled to curb any job uncertainty which has led to unhealthy tactics such as understaffing and overworking. But in the face of these issues, the industry has stayed driven to thrive. From February to April 2020, manufacturing employment levels had declined by -17%. But this decline didn’t last long. No more than two months later in May, employment levels began to rise again. And consequentially, the unhealthy habits were slowly forced out of the door. This demand for continuous productivity has since amounted to 1.7 million full-time, well-paying jobs.

Through the excessive challenges to stabilize, the industry has come to learn that it may never operate the same. The job landscape has changed. The supply chain has become complex. New compliances need to be met. But there’s one thing that will always remain; the value that this industry continues to bring.

Throughout this period of transition, many are intrigued to know the direction the manufacturing industry is heading. Let’s dive into the latest manufacturing industry trends to watch out for.

Efforts to reduce labor shortages

A particular focus for the manufacturing industry is finding ways to fight labor shortages. A recent survey from Canadian Manufacturers & Exporters found that more than 80% of respondents are currently facing labor and skills shortages. Employers have long known that if it continues, rising wages, inflation and supply chain issues will persist. But thinking more long-term, many leaders will fear that certain threats will rear their ugly heads. The potential of a halt in GDP growth and a recession are enough to force the industry into action.

How can organizations combat this?

The reduction in labor has caused organizations to lose many of their qualified and experienced workforce. This has caused a growing manufacturing skills gap. Many believe that this is down to aging workforces. But also, the changing skills required to operate newer technology are not being addressed. Maybe organizations are turning a blind eye to skilled recruits. Is it desperation to get employees on board quickly? Or a poor recruiting process? Whether they choose to train their employees or fight for the highest skilled in the market. It’s a time-consuming process.

A purposeful trend

The Manufacturing Institute revealed that it takes an average of 70 days to recruit skilled workers. But even during these challenging times, the manufacturing industry had a plan. Rather than let a trend dictate their destiny, they purposefully developed their own. Their new trend is putting additional focus on attracting and retaining a new generation of workers. Now we know this sounds like common practice across many industries. But the manufacturing industry has rarely had to fight for top talent.

It all begins with designing an authentic recruitment message which accurately describes the job demands. Due to nearly 40% of new hires leaving within the first year, it’s important that organizations focus on employing people who fully understand their responsibilities. But even if they do, they need to feel engaged.

You can hire all the talent in the world. But without employees feeling fully engaged in your organization and its culture, they’ll struggle to perform at their best. So, an effective onboarding process may be the key to making them feel engaged. Also, respecting their work/life balance. Employee burnout became prevalent throughout the early stages of the pandemic. Now that organizations are more aware of the effects of overworking and understaffing, they can plan to ensure that it doesn’t happen. But how best can they achieve this?

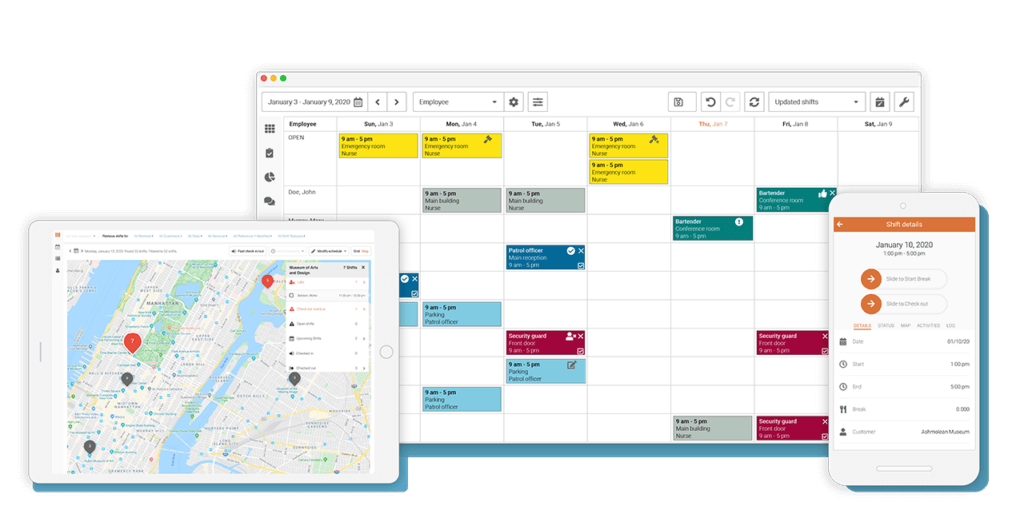

Employee scheduling software

It’s no secret that the manufacturing industry strives for automation. But for now, we’re sure that best-of-breed employee scheduling software can reduce labor shortages. And no, it doesn’t only save the organization money through an optimized schedule. It also protects your workforce too.

Celayix’s employee scheduling software offers time and attendance features that give your employees autonomy over their schedules. Tools such as employee availability gives employees the opportunity to choose when they’re available. Or self-scheduling and shift bidding, which offer the chance for them to pick from the shifts available. Even better, they can view all of this within an app. Which will allow them to instantly communicate with you at any time. Maybe encouraging feedback can make a difference to an organization’s processes. If a supporting culture means that much too them.

As we’re sure you’re aware, work-life balance is crucial for a healthy workforce. And we know that employee scheduling software and its benefits are a big advocate of that. But let’s look at the most obvious form of keeping your workforce at its healthiest.

Additional health and safety practices

Now we wouldn’t usually distinguish health and safety as a manufacturing industry trend. As it’s something that should be observed and fostered every day. But the recent pandemic has ‘revolutionized’ the practices we undertake to ensure maximum safety. None more so than this industry, which cannot operate using the popular and safer work-from-home policy.

Integrating new practices

Falling into the essential worker’s category, manufacturers have been left with no choice but to adapt to new on-site practices. And we anticipate there will be more in the pipeline. Here’s some you’ll be familiar with:

- If sick, employees must stay at home.

- Masks must always be worn.

- Social distancing remains at all times.

- Increased health and safety checks.

- Additional workforce training.

So, how do organizations manage this?

To ensure the best management of this “trend”, manufacturing organizations must first realize the uniqueness of their own environment. An assessment needs to be made to ensure the newest government health and safety standards can be safely met on site. If not, it’s their duty to change this.

Management has been required to conform to the latest compliances. Which has resulted in additional workforce training. The transformation of health and safety has come as a negative pressure to the manufacturing industry. Increasingly large amounts of time are being spent dealing with the newer inconsistencies of the pandemic. This unpredictability is causing an unsettling fluctuation in production levels. But the law is the law, and health and safety will always be paramount in any workplace at any time. Even if it is at the detriment of time and money.

Away from the pandemic and its effects, organizations are pushing hard to plan for the future. Let’s take a look at how they’re doing this.

Post-pandemic planning

The unfortunate reality that we find ourselves in means that we’ve grown to expect frequent change. One trend we expect to see is organizations planning to execute what they potentially couldn’t during these current times. Hitachi Solutions devised a theory of three phases, referred to collectively as “The Reset”. Respond. Recover. Renew.

Which phase now?

The majority of manufacturing organizations were equipped enough to surpass the response phase. New measurements are in place to maximize workforce safety and keep the industry operating at a fast=paced level. However, some believe the majority surpassed the response phase a while ago.

Many industries continue to adopt and integrate new practices to progress their recovery. This could be restarting activities, rehiring, reassessing their budget. Or even just reopening. But it’s clear that many in the manufacturing industry are comfortably into the third phase. They’re moving forward and they have a new strategy in place. The strategy they have created is layered with a new foundation. This new foundation is based on their learnings and will give them the knowledge and experience to handle forthcoming difficulties astutely. For the opportunist in the manufacturing industries, this is a chance to reduce or retire old operating models. A time to reinvent and revolutionize.

If post-pandemic planning is managed efficiently, organizations can move to the next “phase”. For those who have reached this stage, it may be time to revisit that feeling of nostalgia. To a time when the industry was about growth and not recovery. Like onboarding new technology.

Enter, automation.

The one that almost got away

This manufacturing industry trend is not a new phenomenon. More a paused one. But it’s recently resurfaced due to the market gaining more financial power with less restriction. Now that many organizations have stabilized, they can put more focus on growth through newer processes.

Automation aims to completely remove any non-value or low-value processes. And although the manufacturing industry is expected to grow by 6.3% through 2020-25, they first need to regain lost time and money. Automation seems the most sensible approach if there not using it already. Either way, we anticipate it to be a critical factor at some point.

Manufacturing employees look away now. Manufacturing automation has a significant emphasis on increasing production capacity while reducing error and cost. Often through using machinery over humans. Typically, electromechanical systems. But in many cases, these are a future though. And not every manufacturer wants to operate with automation.

So, what have we discovered about the manufacturing industry trends of today?

Discovering a redefined path

The current manufacturing industry trends are a sign of the times. The recent pandemic has left many industries suffering with a loss of skilled employees, money, and general direction. Despite this, the manufacturing industry has had no choice but to navigate through the difficulties of new demands. And we’re starting to realize that it’s gained one distinct trend from all of this. The future is heading down a redefined path.

The majority of current manufacturing industry trends can be perceived to be forced. The pandemic has caused a landslide of negativity. But now the tides are turning. The industry is finding its strength again and its redefined path will be carried by newer knowledge. Now that the supply chain and labor shortages are seemingly under control, they can focus on growing.

It’s time to put their focus back on the long list of desires they had before this interruption. Improving their employee culture. Integrating a recruitment process that draws skilled workers. Adopting new technologies that will make the industry far superior to the one at present. We’re expecting to report a completely different set of trends in years to come. For those dedicating their livelihoods to the manufacturing industry, it’s your time to create them.